With food spoilage contributing to 14% of global food production losses, innovations that enhance oxygen resistance while reducing plastic dependency are becoming mission-critical. Nestlé is leading this charge by developing next-gen oxygen-barrier substrates that match or exceed the performance of traditional plastics without the environmental cost.

The company is reengineering packaging materials at the molecular level to meet and exceed oxygen transmission rate (OTR) thresholds required for food-grade applications. Recent studies shown that bio-based nanocoatings can achieve OTR values below 0.1 mL/m²/day, rivaling multilayer plastics while improving recyclability.

Nestlé’s foray into using layer-by-layer assembly techniques with bio-based materials to create transparent, self-cleaning, and moisture-resistant coatings, signals a convergence of materials science, sustainability, and scalable innovation.

This research study explores how Nestlé’s latest research innovations in oxygen-barrier substrates is helping redefine packaging standards and unlock whitespace for R&D leaders across the industry.

Latest Research and Innovations by Nestlé in Oxygen-Barrier Substrates

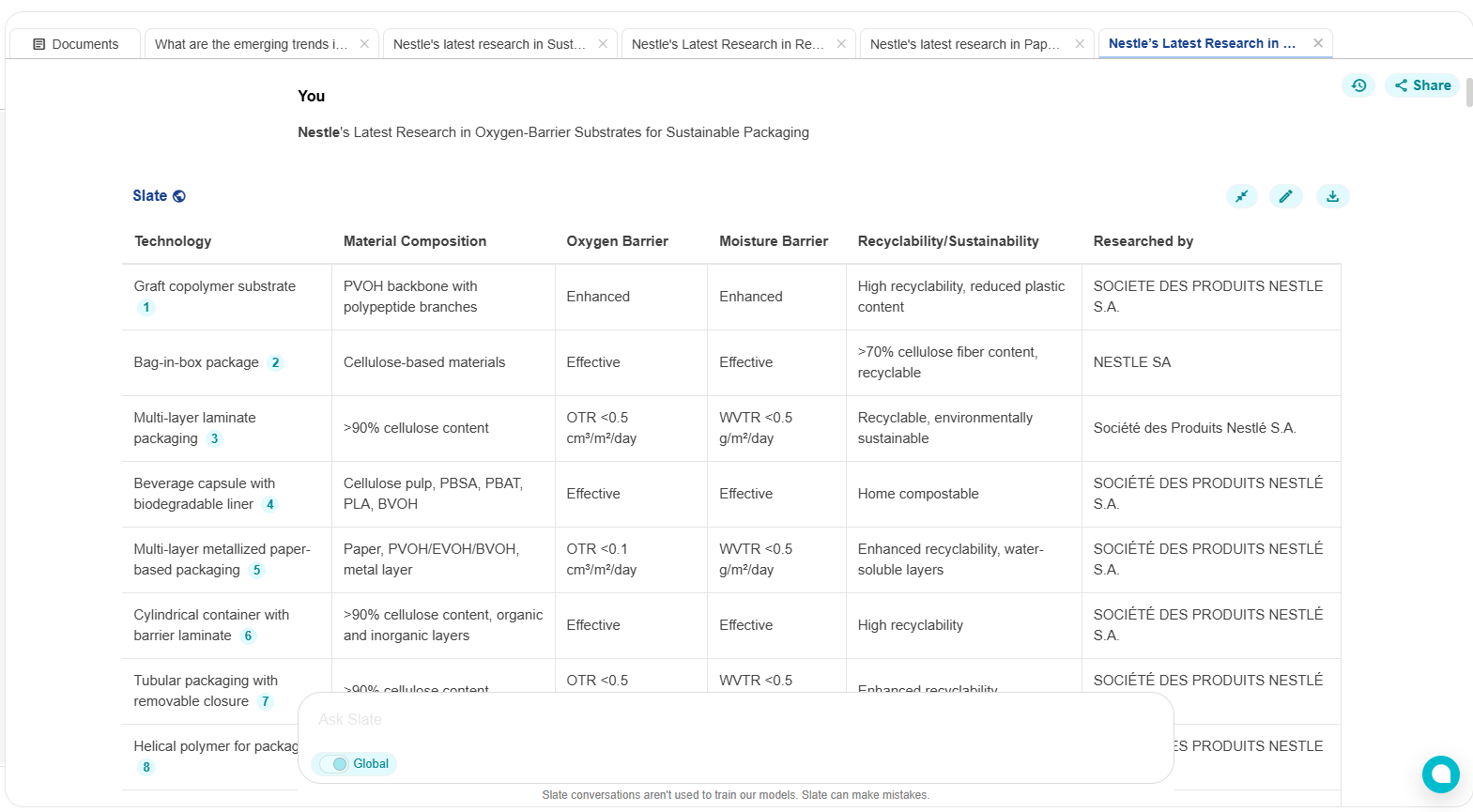

Nestle’s latest research in oxygen-barrier substrates for sustainable packaging focuses on innovative materials and designs that enhance barrier properties while promoting sustainability.

Its evolving innovations are categorized into key technical domains such as oxygen-barrier polymers and coatings, cellulose pulp-based packaging materials, metallized paper-based packaging, and multi-layer barrier laminates.

Nestlé invests across a diversified innovation pipeline from plant-based barrier materials to nanocomposite substrates to reduce plastic dependency while maintaining food-grade protection standards. Below is the comparison of all the potential solutions.

External innovation discovery platforms like Slate, helps you find competitors’ advancements in their focus research area. It also supports global tracking, allowing strategic intelligence professionals to monitor Nestlé’s material innovation activities across regions and market segments.

Let’s explore the key themes and features identified from the research:

1. Graft Copolymer-Based Oxygen-Barrier Substrates

Vinyl Alcohol Polymer Backbone: Nestlé uses a graft copolymer with a vinyl alcohol polymer backbone, such as polyvinyl alcohol (PVOH), and polypeptide branches like collagen.

It enhances mechanical resilience and barrier properties against oxygen and moisture. This innovation significantly reduces plastic content, improving recyclability and making it suitable for standard recycling processes.

This approach reduces overall plastic content while maintaining high barrier performance, aligning with emerging EPR (Extended Producer Responsibility) regulations in Europe and APAC. It also serves as a benchmark for others seeking to balance performance with recyclability.

2. Cellulose-Based Packaging Solutions

Two key developments stand out in Nestlé’s cellulose strategy:

Bag-in-Box Formats: Nestlé has redesigned conventional bag-in-box formats using cellulose-based films. It enhances sustainability and recyclability. The design ensures that the box and the bag are recycled together, minimizing environmental impact while maintaining product integrity by limiting exposure to oxygen and moisture.

High Cellulose Content Laminates: Packaging units featuring multi-layer laminates with high cellulose content provide effective oxygen and moisture barriers, significantly improving the preservation of contents and extending shelf life.

This direction reflects broader trends in Scandinavian and DACH markets, where fiber-based packaging solutions are rapidly gaining regulatory and consumer traction.

3. Multilayer and Metallized Paper-Based Packaging

Nestlé’s innovation in metallized paper incorporates:

- Organic barrier layers (e.g., PVOH)

- Inorganic elements (e.g., micro-aluminum coatings)

These layers create water-soluble, high-barrier structures that are easier to recycle than traditional plastic/aluminum laminates. This hybridization is particularly relevant in snack food and confectionery sectors, where barrier needs are high, but plastic reduction mandates are tightening.

4. Biodegradable and Compostable Beverage Pods

Multi-layered Structure: Beverage pods with a multi-layered structure, including a primary paper-based layer and a secondary oxygen barrier layer, are designed for home compostability. These pods maintain beverage quality while addressing sustainability concerns in single-serve packaging.

5. Advanced Polymer Designs

Helical Structure Polymers: Nestlé’s research into polymers with aromatic cyclic moieties forming a helical structure enhances moisture and gas barrier properties, offering a potential solution for reducing plastic waste while maintaining food safety and quality.

These materials show promise for applications across dry goods and frozen food categories, where moisture ingress is a major cause of product spoilage.

Track Nestlé’s Next Breakthrough in Packaging R&D

Nestlé is not merely adapting to sustainability trends but also engineering them. Nestlé is building a formidable market by pioneering oxygen-barrier packaging solutions that achieve regulatory readiness and market differentiation.

Competitors must recognize that the traditional trade-offs between barrier properties and sustainability are being systematically dismantled. Nestlé’s focus on polymer redesign, bio-based layering, and metallized paper recyclability is a roadmap for how R&D investment can meet regulatory compliance and consumer preference for sustainable goods.

These innovations also reinforce Nestlé’s position in industry coalitions like the Sustainable Packaging Coalition and its alignment with the Ellen MacArthur Foundation’s New Plastics Economy, further pressuring competitors to adopt similarly science-driven strategies.

To stay competitive and informed on Nestlé’s ongoing R&D initiatives and packaging breakthroughs, leveraging tools like Slate is critical.

With Slate – an external innovation discovery platform

- Access consolidate Nestlé’s latest packaging R&D and innovations from diverse sources (patents, research reports, and scientific literature) into one actionable view

- Explore new packaging solutions with detailed performance and environmental impact data

- Monitor competitors’ latest material innovations, packaging strategies, and technology trends to inform your R&D roadmap

- Get data-backed answers to your packaging innovation questions via Slate’s AI research assistant