The global compostable biopolymers market is set to grow rapidly, reaching USD 12.2 billion by 2030. Amidst this shift, Nestlé is making bold strides with a comprehensive innovation pipeline focused on bio-based formulations, scalable pilot programs, and ecosystem partnerships.

As regulations tighten and consumer demand for sustainable products rises, compostable biopolymers are emerging as a strategic alternative to fossil-based plastics for global brands. Nestlé’s approach stands out for its scientific rigor and holistic lifecycle view. It introduced home-compostable coffee capsules for its Nespresso line, made from 82% paper pulp and a compostable biopolymer film that preserves product integrity via enhanced oxygen barriers.

Nestlé is developing packaging materials with synthetic and natural bio-based polymers, using nanotechnology and novel processing techniques to ensure they degrade harmlessly while maintaining the functionality of traditional plastics.

The company has also introduced bio-based lids and scoops made from sugarcane, with up to 95% renewable content, reducing reliance on fossil-derived plastics and aligning with its goal to make 100% of its packaging recyclable or reusable by 2025.

This article unpacks Nestlé’s latest advancements in compostable biopolymers and what its mean for the rest of the industry.

Nestlé’s Latest Research in Compostable Biopolymers

Nestle’s latest research in compostable biopolymers for sustainable packaging focuses on developing eco-friendly alternatives to traditional petroleum-based plastics. This research aims to reduce environmental impact and promote a circular economy by utilizing renewable resources.

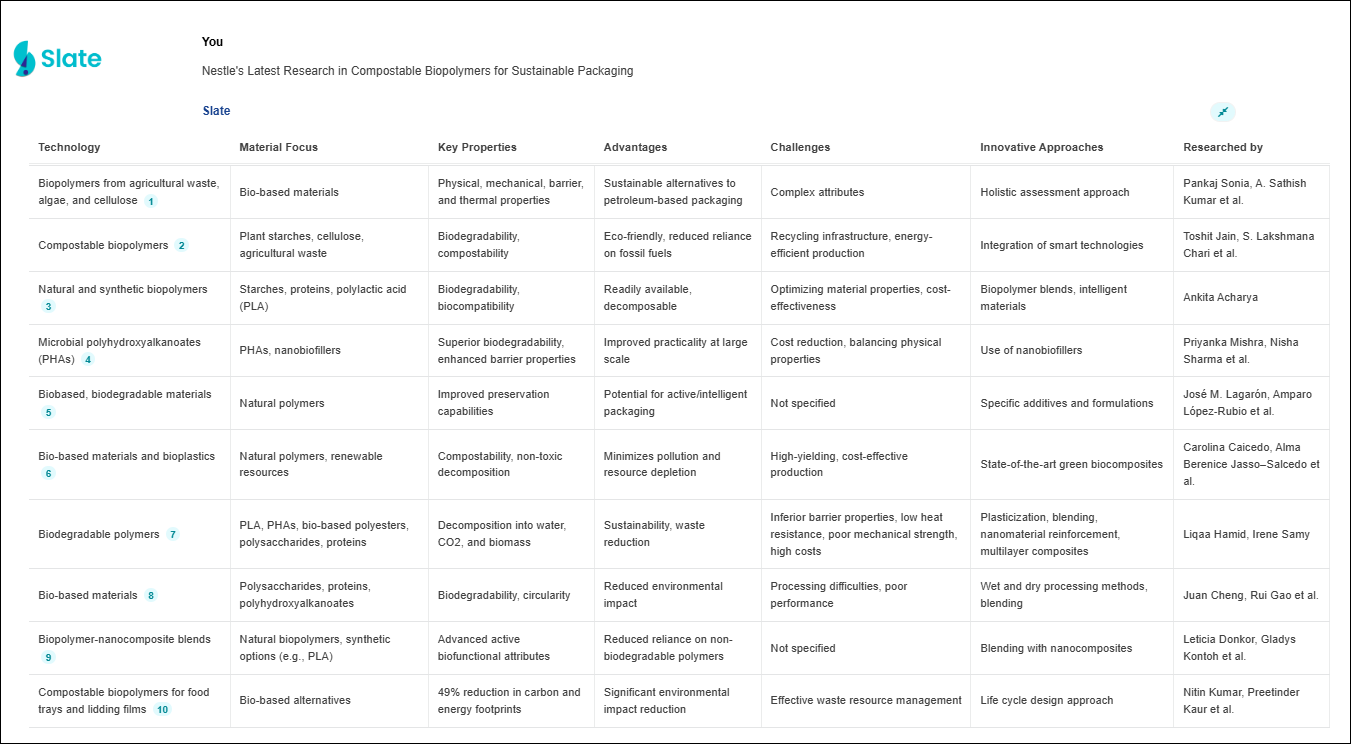

Nestlé is making its R&D investments across a comprehensive set of biopolymer-based packaging innovations, illustrating how the company is systematically building its capabilities in the domain.

Rather than limiting its innovation to a single material or format, Nestlé is exploring a multidimensional material strategy in compostable biopolymers, including multi-layer flexible materials, barrier-enhanced biopolymers, biodegradable capsules and pods, and more.

As R&D heads and innovation managers aiming to track such rapid advancements, navigating scattered research papers, patents, and sustainability reports can be overwhelming. This is where AI-powered tools like Slate can help consolidate Nestlé’s latest packaging research and innovations into structured, actionable insights.

Slate converts raw scientific research into strategic foresight and empowers R&D teams to anticipate market shifts and avoid being blindsided by competitors’ advances. It enables researchers to track what Nestlé is researching, how quickly it’s progressing, which material classes are gaining traction, and where investment priorities are shifting.

Let’s explore the key themes and features identified from the research:

1. Development of Biopolymers

Nestlé’s recent work explores the development of biopolymers that offer the critical advantage of compostability and reduce reliance on petroleum-based sources.

Bio-based Materials: The research explores biopolymers derived from agricultural wastes, algae, cellulose, plant starches, and proteins. These materials are biodegradable and compostable, offering a sustainable alternative to conventional plastics.

Synthetic and Natural Options: Key materials include polylactic acid (PLA), polyhydroxyalkanoates (PHAs), bio-based polyesters, and natural polymers like starches and proteins. These materials decompose into non-toxic components, reducing pollution and resource depletion.

2. Enhancing Material Properties

A recurring challenge for compostable packaging is mechanical fragility and limited barrier performance. Nestlé’s R&D addresses this by incorporating nanobiofillers such as cellulose nanocrystals and nanoclays into biopolymer matrices.

Nanocomposites and Blends: Integrating nanobiofillers and biopolymer blends are explored to enhance mechanical strength, barrier properties, and thermal stability. This approach aims to overcome challenges such as low heat resistance and poor mechanical strength.

Advanced Technologies: Innovative technologies like high pressure, cold plasma, microwave, ultrasound, and ultraviolet light are used to improve the barrier and mechanical properties of biopolymers, making them suitable for various packaging needs.

3. Sustainability and Circular Economy

Nestlé’s research strongly emphasizes lifecycle-based design, which reduces the impact of raw materials and optimizes degradation and recycling pathways. Biopolymer solutions are assessed across their environmental impact spectrum, from cradle to grave.

Life Cycle Design: The research emphasizes designing the entire life cycle of biopolymers, from raw material selection to end-of-life disposal, to maximize sustainability benefits. This includes introducing sustainability criteria for biobased feedstock and implementing effective waste resource management strategies.

Environmental Impact Reduction: Studies highlight a significant reduction in carbon and energy footprints when substituting conventional fossil-based polymers with bio-based alternatives, aligning with global environmental goals.

4. Challenges and Future Directions

Nestlé’s strategy includes advocating for standardized global biodegradation protocols, especially in emerging markets, and investing in pilot composting projects.

Technical and Economic Barriers: Challenges such as higher production costs, technical limitations, and the need for specialized waste management infrastructure are noted. Strategies to address these include developing standardized biodegradation protocols and investing in waste management systems.

Integration of Smart Technologies: The research explores integrating smart technologies to enhance the efficacy of biopolymer-based solutions and ensure product safety and quality during storage and transportation.

Uncover Nestlé’s Next Innovation in Sustainable Packaging

Nestlé’s comprehensive approach to compostable biopolymers, combining nano-enhanced materials, smart packaging technologies, and lifecycle sustainability signals a significant shift in the packaging industry. Companies that fail to keep pace risk regulatory setbacks, diminished consumer trust, and loss of market share in environmentally conscious segments.

For R&D and sustainability teams, continuously monitoring competitors’ research breakthroughs and innovation roadmaps is essential to maintaining a competitive edge. Leveraging advanced intelligence platforms that synthesize patent data, scientific publications, and market trends can provide timely insights, enabling faster benchmarking and informed strategic decisions.

To stay ahead of Nestlé’s evolving packaging innovations and identify emerging opportunities, integrating structured, real-time intelligence into your R&D strategy is critical for long-term success in sustainable packaging.

With Slate – an external innovation discovery platform

- Access consolidate Nestlé’s latest packaging R&D and innovations from diverse sources (patents, research reports, and scientific literature) into one actionable view

- Explore new packaging solutions with detailed performance and environmental impact data

- Monitor competitors’ latest material innovations, packaging strategies, and technology trends to inform your R&D roadmap

- Get data-backed answers to your packaging innovation questions via Slate’s AI research assistant