The multi-layer flexible packaging industry is facing a terminal diagnosis. The structures that have defined shelf-life and high-performance barriers for decades like PET/PE, PA/PE, and aluminum foil laminates are now classified as waste, destined for landfill or incineration under the EU’s aggressive circular economy mandates.

The deadline is 2030. By then, every piece of packaging must be demonstrably recyclable at scale. For packaging engineers and FMCG manufacturers, the immediate, existential challenge is how do we replace the high-performance functional barriers that protect food and pharmaceuticals without violating the strict new rules on Design for Recycling and mandatory recycled content?

This is the ultimate test of material science. The convergence of PPWR and SUPD has created a pivotal, non-negotiable moment where the functional barrier must become a facilitator of circularity, not an impediment.

Regulatory Deep Dive: The Compliance Imperative

The PPWR mandate that all packaging must be recyclable by 2030 is the most critical hurdle for functional barriers. This is defined not just by technical possibility but by the ability to be “recycled at scale” by 2035, meaning it must be collected, sorted, and processed effectively by existing infrastructure across EU Member States.

| Regulatory Element | Key Barrier Implication | Impact on Traditional Materials |

| PPWR Art. 6: DfR by 2030 | Barrier layers must not contaminate the main polymer stream, nor inhibit sorting or processing. | Severe: Multi-material laminates (PET/PE, PA/PE, most EVOH-containing structures) that are currently non-separable are non-compliant. |

| PPWR Art. 7: Minimum Recycled Content | PCR targets (e.g., 30% for contact-sensitive PET by 2030, 10% for other contact-sensitive plastics) require PCR that meets EFSA food-contact safety standards. | Challenging: Maintaining high barriers (OTR, WVTR) using PCR is technically demanding and requires advanced purification. |

| SUPD: Single-Use Plastic Restrictions | Direct ban on certain single-use plastics (e.g., specific food containers, cutlery) and the requirement for tethered caps on beverage containers. | High: Forces a material shift for key FMCG formats and necessitates redesign of closures (which must also be recyclable). |

| PPWR: Ban on Substances of Concern | Bans on substances like Per- and Polyfluorinated Alkyl Substances (PFAS) in food contact packaging. | Immediate: Requires complete reformulation and validation of grease/oil barrier coatings, often reliant on fluorinated chemistries. |

The most immediate and profound impact is the mandated move away from multi-material flexible packaging towards mono-material or fiber-based structures.

Material Solutions & Technology Assessment

The transition to compliant packaging is a complex, time-sensitive technology scouting mission. The rapid emergence of new, DfR-compatible materials and suppliers has created a constant state of flux.

The core challenge for researchers is not the existence of solutions, but the speed and accuracy of discovery: how can technical teams rapidly filter the global noise of emerging technologies, validate supplier claims against stringent PPWR criteria, and confidently pivot R&D efforts to proven, scalable solutions?

This demanding requirement for efficient external innovation discovery and technical validation is where specialized platforms provide a critical advantage.

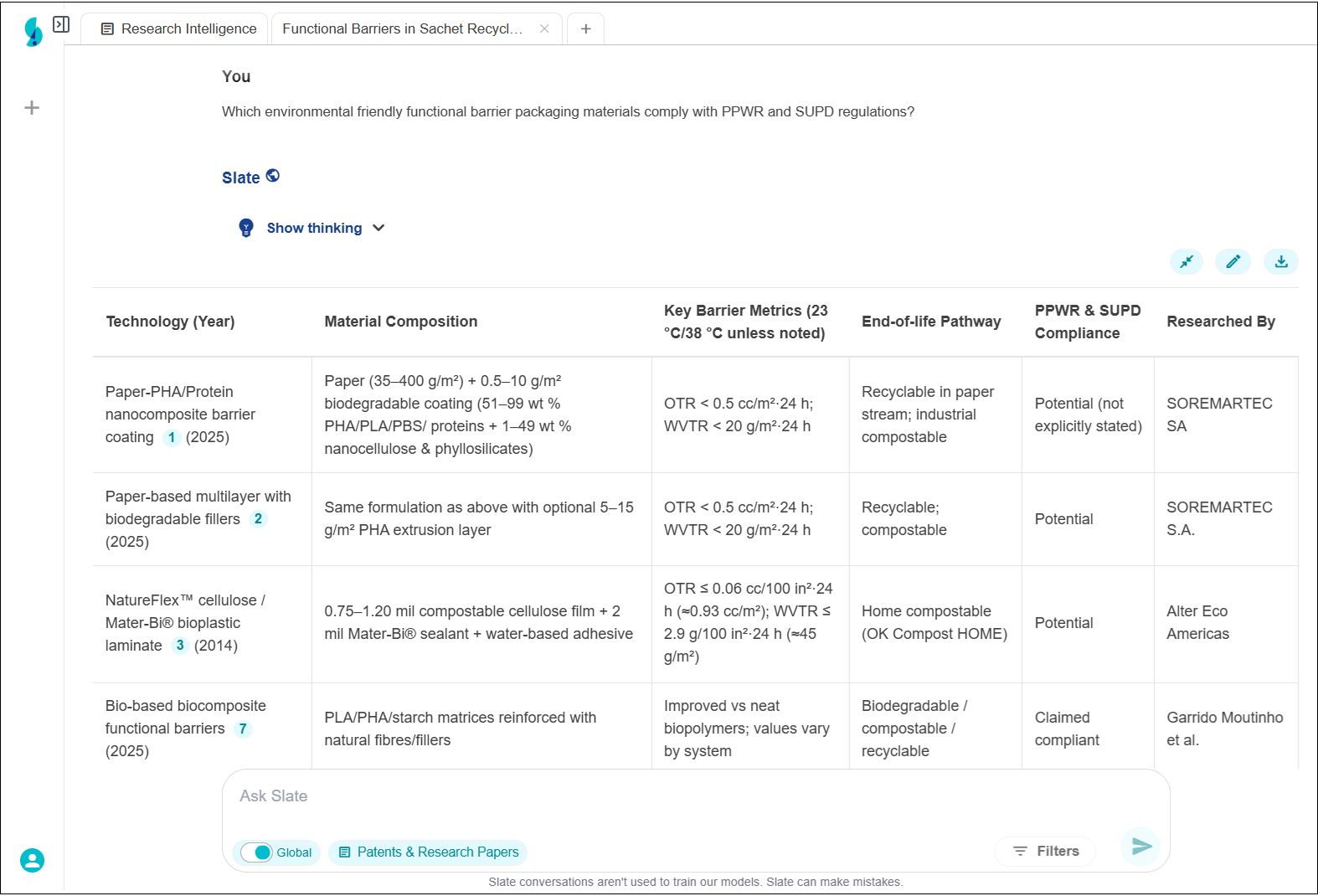

We used Slate, an innovation discovery platform for packaging that brings together verified insights from patents, research papers, and innovation pipelines across the global packaging ecosystem.

Monomaterial High-Barrier Plastics

The DfR guidelines strongly favor structures composed of ≥95% of a single polymer like PE or PP to ensure successful mechanical recycling into a high-quality stream.

| Solution | Mechanism & PPWR Alignment | Challenges & Trade-offs |

| All-PE/All-PP Structures | Uses Biaxially Oriented Polyethylene (BOPE) or specialty PP to provide stiffness and heat resistance, combined with a PE/PP sealant layer. Barrier achieved via co-extrusion with minimal layers. | Performance: Often provides Medium-to-High barrier, but rarely Ultra-High barrier with OTR<1 cc/m2/day needed for sensitive products. PCR integration at high levels remains complex. |

| Polyolefin with SiOx/AlOx Coating | A mono-polyolefin film is coated with a microscopically thin, inorganic barrier layer like Silicon Oxide or Aluminum Oxide via vacuum deposition. | Compliance: The inorganic layer is so thin that it does not typically interfere with the PE or PP recycling process, often passing RecyClass protocols. |

| EVOH Reduction/Replacement | Traditional EVOH is a potent contaminant in polyolefin recycling. Monomaterial strategies minimize its use, or utilize tie layers designed for EVOH delamination in the recycling process. | Compliance: EVOH content must be below critical thresholds (typically <5%) to avoid de-rating the package’s recyclability grade. |

High-Barrier Paper and Fiber Solutions

Fiber-based packaging is inherently aligned with sustainability goals. The compliance hurdle lies in ensuring the functional barrier coating does not contaminate the fiber stream and allows for effective fiber recovery during pulping.

| Solution | Mechanism & PPWR Alignment | Challenges & Trade-offs |

| Water-Based Dispersions | Advanced water-soluble or dispersible coatings like acrylics or bio-polymers replace PE-extrusion layers to provide an oil/grease/moisture barrier. | Compliance: Must be certified by bodies like CEPI as fully recoverable (fiber separation ≥90%) after pulping. Highly favored under PPWR. |

| Paper with Mono-Polymer Liner | Uses a minimal, detachable PE or PP liner on a fiber structure like liquid cartons. | Compliance: The liner must be designed for easy separation during the recycling process to ensure high-quality fiber and plastic fractions. Difficult to implement for flexible formats. |

Bio-Based and Targeted Compostable Polymers

The use of bio-based materials and compostable polymers are two separate issues under PPWR.

| Solution | Mechanism & PPWR Alignment | Challenges & Trade-offs |

| Bio-Based “Drop-In” Polymers | Bio-PE and Bio-PET are chemically identical to their fossil counterparts, but derived from biomass like sugar cane. | Compliance: Fully compliant with PPWR DfR and recycling rules, as they recycle seamlessly with their fossil equivalents. They primarily address carbon footprint reduction. |

| Compostable Polymers (PLA,PHA,PBAT) | Polymers designed to break down in an industrial composting facility (EN 13432 standard). They can offer functional moisture/grease barriers. | Compliance: PPWR strictly limits their use to applications where they help manage biowaste like fruit labels, tea bags, coffee pods. They are generally banned for other packaging to prevent contamination of mechanical plastic recycling streams. For most FMCG and beverage applications, compostable is not the compliant pathway. |

Chemically Recycled and Recycled-Content Polymers

Meeting the PPWR’s mandatory PCR targets requires mechanical recycling and technologies capable of producing food-contact-compliant material, particularly for high-barrier applications.

| Solution | Mechanism & PPWR Alignment | Challenges & Trade-offs |

| Chemical Recycling (Advanced Recycling) | Processes like pyrolysis or depolymerization break down mixed plastic waste including non-recyclable multi-layers into basic monomers or oils. These are then repolymerized into virgin-quality plastic (rPET,rPE,rPP). | Compliance: This process delivers food-grade PCR that meets the stringent EFSA requirements for food contact, crucial for high-barrier layers where safety is paramount. |

| Mechanical PCR in Non-Food Barriers | High-quality PET (rPET) is widely used in beverage bottles. For non-food applications (e.g., home care, industrial), mechanical rHDPE and rPP can be incorporated into barrier structures. | Compliance: Directly addresses PPWR PCR mandates. However, PCR tends to have reduced barrier performance and increased color/odor, limiting its use in pure barrier layers without protective virgin material. |

Industry Adoption & Future Outlook

Leading beverage and food manufacturers are already deploying compliant solutions, demonstrating commercial readiness:

Beverage Closures (SUPD): Brands are trialing fiber-based bottles with bio-based barrier coatings to reduce reliance on PET and aluminum. The transition to PP and HDPE tethered caps on single-use plastic bottles is nearing completion. The PPWR’s emphasis on DfR mandates that the tethering mechanism must not disrupt the PET bottle recycling stream, a technical detail addressed through extensive engineering validation.

Amcor developed PET bottles with silicon oxide (SiOx) coatings, which offer glass-like clarity while cutting carbon footprints by 30%. These bottles are fully recyclable and retain a premium aesthetic.

Dry Food Pouches (PPWR DfR): Several major snack and coffee brands are transitioning from PET/Alu/PE to Mono-PP or Mono-PE pouches. This required an R&D investment in new polyolefin grades and coating technologies to secure the necessary OTR/WVTR while maintaining seal integrity on existing high-speed VFFS and HFFS packaging lines.

The future of functional barriers is in material synergy:

- Chemical Recycling (PCR): The only scalable route to EFSA-compliant food-grade PCR for polyolefins will involve advanced recycling technologies that can clean and depolymerize mixed plastic waste, including materials that contain minor functional barrier layers. This will be essential to meeting the PPWR’s PCR targets.

- Bio-Based Feedstocks: While not directly addressing end-of-life, the use of bio-based PE or PP helps meet corporate GHG reduction goals without compromising PPWR DfR compliance, as their chemical composition is compatible with existing recycling streams.

- Digital Watermarks: Future DfR assessments will be enhanced by technologies like digital watermarking (HolyGrail 2.0), which can more accurately sort mono-material flexible packaging from mixed waste, improving the quality and scale of mono-PE and mono-PP recycling.

The Road Ahead: Aligning Research with Regulation and Market Readiness

As PPWR and SUPD evolve, compliance will become a competitive differentiator rather than a constraint.

The success for functional barriers hinges on the immediate transition to Mono-PE/Mono-PP structures with SiOx/AlOx coatings to achieve Grade A or B DfR compliance. Simultaneously, de-risking the supply chain by securing chemically recycled polymers (rPET,rPE) is essential to meeting ambitious 2030 and 2040 mandatory minimum food-contact PCR targets.

The constant evolution of these requirements and the rapid emergence of new solutions means that the packaging material landscape is shifting faster than ever. Keeping pace with these global material science and technical developments is a challenge few R&D teams can meet alone.

To efficiently navigate this complexity and rapidly identify the next generation of compliant barrier technologies, external innovation discovery is critical. Tools like Slate help researchers and material scientists cut through the noise, finding verified answers to specific technical challenges and conducting targeted technology scouting to secure a competitive edge in the evolving circular economy.