Nestlé is under increasing pressure to find materials that offer the same level of performance as conventional packaging while also being eco-friendly. Nestlé’s cellulose-based barrier materials have emerged as a strong candidate in this area. These materials exhibit impressive barrier properties against oxygen and moisture and promise to be more sustainable than plastic-based alternatives.

Cellulose insulation already boasts an impressive 75–85% recycled paper fibers, primarily sourced from post-consumer waste like newsprint, positioning it as one of the most recycled-content-rich materials on the market. The embodied energy required for producing cellulose-based products is 20 to 40 times lower than that of traditional furnace-made insulation, highlighting its efficiency and significantly lower environmental footprint.

These properties make cellulose a sustainable and effective choice, especially in areas like packaging, where barrier properties are crucial. Recent research shows cellulose-based films exhibit oxygen permeability rates that are on par with petroleum-based materials, making them highly suitable for food and beverage packaging.

Nestlé is heavily investing in research to develop cellulose-based solutions that could revolutionize the packaging industry. This is part of its commitment to reducing its environmental footprint.

Latest Research and Innovations in Cellulose-Based Barrier Material by Nestlé

Nestlé’s recent research focuses on several innovative approaches to utilizing cellulose for barrier materials. These advancements highlight the company’s ability to balance sustainability with high-performance standards, setting the stage for scalable, eco-friendly packaging solutions.

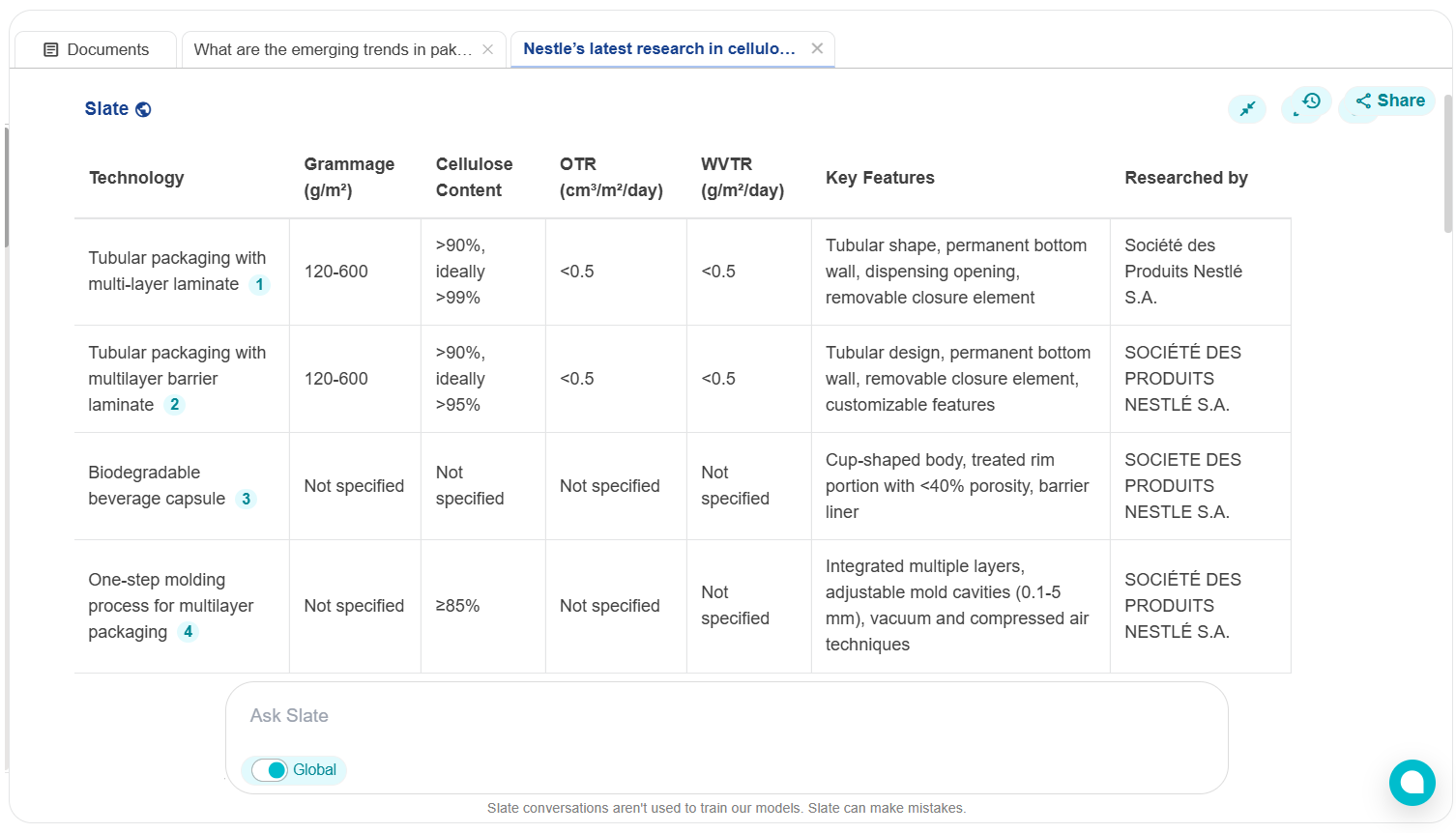

Slate, our external innovation discovery platform helps you find competitors’ advancements in their focus research area. It provides research findings in tabular form to easily grasp the information and compare all results across custom parameters to get a holistic view of the solutions.

Researchers can customize the view to prioritize key variables such as oxygen transmission rate (OTR), water vapor transmission rate (WVTR), cellulose content, or structural features for side-by-side comparisons across multiple innovations.

It accumulates all the data from patents, scientific publications, and technical specs, connects the dots across the research findings, and reveals what a company is doing and where it’s heading.

Let’s explore the key themes and features identified from the research:

1. Multi-layer Laminate Packaging

Nestlé’s multi-layer laminate packaging design is a breakthrough in achieving high barrier performance and environmental sustainability.

Cellulose Support Layer

One of the cornerstone innovations in Nestlé’s research is the development of multi-layer laminate packaging that incorporates a cellulose-based support layer. This packaging structure provides exceptional barrier properties, with the cellulose content exceeding 90% and reaching over 99% in some cases. These packaging solutions demonstrate low oxygen transmission rates (OTR) of less than 0.5 cm³/m²/day and low water vapor transmission rates (WVTR) of less than 0.5 g/m²/day. This means that products like food or beverages will have extended shelf life, which is critical in maintaining product quality and safety.

Environmental Sustainability

The use of cellulose in this multi-layer laminate design contributes to the sustainability of the packaging. Not only does the high cellulose content improve recyclability, but it also reduces the reliance on petroleum-based plastic materials. Including a removable closure element made from a cellulose-based laminate further enhances the recyclability of the packaging. This packaging design aligns with Nestlé’s commitment to reduce its environmental impact, particularly by increasing the use of renewable, biodegradable materials.

2. Biodegradable Beverage Capsules

Nestlé has also made advancements in creating cellulose-based beverage capsules. These capsules are designed to offer improved functionality and environmental benefits, addressing a growing market demand for biodegradable and compostable alternatives to plastic and aluminum capsules.

Cellulose Pulp Construction

The capsule’s body is made from cellulose pulp. It features a cup-shaped design with a bottom wall, lateral side walls, and an outwardly extending rim portion. The rim portion is specially treated to reduce porosity, thereby improving its stiffness and reducing water absorbency. This innovative design minimizes the risk of capsules sticking during ejection from brewing units, improving operational efficiency and product quality.

Barrier Liner Integration

To address the need for extended shelf life, Nestlé’s beverage capsules also integrate a cellulose barrier liner. This liner serves as a moisture and oxygen barrier, ensuring that the contents, such as roasted and ground coffee, maintain their freshness and flavor for an extended period. This dual-function design aligns with sustainability goals and meets the high-performance packaging requirements in the food and beverage sector.

3. One-Step Molding Process for Packaging

Nestlé has introduced a novel one-step molding process for cellulose-based packaging that significantly simplifies the production process while improving the quality of the packaging.

Integrated Layer Formation

This one-step process allows the creation of a multi-layer cellulose-based packaging material with integrated layers that are formed simultaneously. By using adjustable mold cavities and vacuum techniques, this method ensures proper layer adhesion and the mechanical strength necessary for high-performance packaging.

High Recyclability

The final product consists of at least 85% cellulose fibers, which are compatible with paper recycling streams, ensuring the packaging’s high recyclability. By reducing the complexity of manufacturing and improving the adhesion between the layers, Nestlé is able to offer a packaging solution that is not only eco-friendly but also easier to produce and recycle.

Uncover Nestlé’s Next Innovation in Sustainable Packaging

Nestlé’s latest research in cellulose-based barrier materials demonstrates that sustainable packaging does not have to compromise on performance. With innovations such as multi-layer laminate packaging, biodegradable beverage capsules, and the one-step molding process, Nestlé is leading the way in transforming the packaging landscape. The company’s commitment to sustainability and innovation ensures it will remain at the forefront of the packaging industry.

Keeping an eye on these developments is crucial for competitors looking to maintain their market position. The shift towards cellulose-based solutions represents a significant opportunity, and companies that fail to adapt may find themselves lagging in an increasingly eco-conscious market.

To track more of Nestlé’s cutting-edge research and developments, use Slate. Stay ahead by accessing the latest insights and closely examining your competitors’ next moves in sustainable innovation.