With over 400 million tons of plastic produced annually, the need for alternatives has never been more urgent. Nestlé’s move to develop compostable pods represents an apparent effort to reduce the plastic waste associated with traditional beverage pods.

By replacing non-compostable plastic with biodegradable materials, Nestlé actively reduces plastic pollution, directly aligning with the company’s broader sustainability objectives.

The global compostable packaging market, valued at USD 103.77 billion in 2024, is anticipated to reach USD 232.47 billion by 2034, growing at a CAGR of 8.4% over the next decade. Nestlé’s latest research, patents, and innovations in this field underscore their commitment to advancing sustainable materials, particularly in single-use beverage pods.

By improving the compostability of its packaging and reducing plastic waste, Nestlé is helping to build a more sustainable future while setting a high standard for others in the industry to follow.

Latest Research and Innovation in Developing Compostable Pods by Nestlé

Nestlé’s recent work in developing compostable pods emphasizes a holistic approach to sustainability, integrating material innovation, functional design, and environmental benefits. But understanding how these innovations compare with those of competitors and how they evolve over time, requires more than isolated research reads.

To uncover such strategic shifts, innovation discovery platform can help to trace Nestlé’s compostable packaging R&D across scientific literature and patent filings. This gives an integrated view of how their compostable pod technology is advancing.

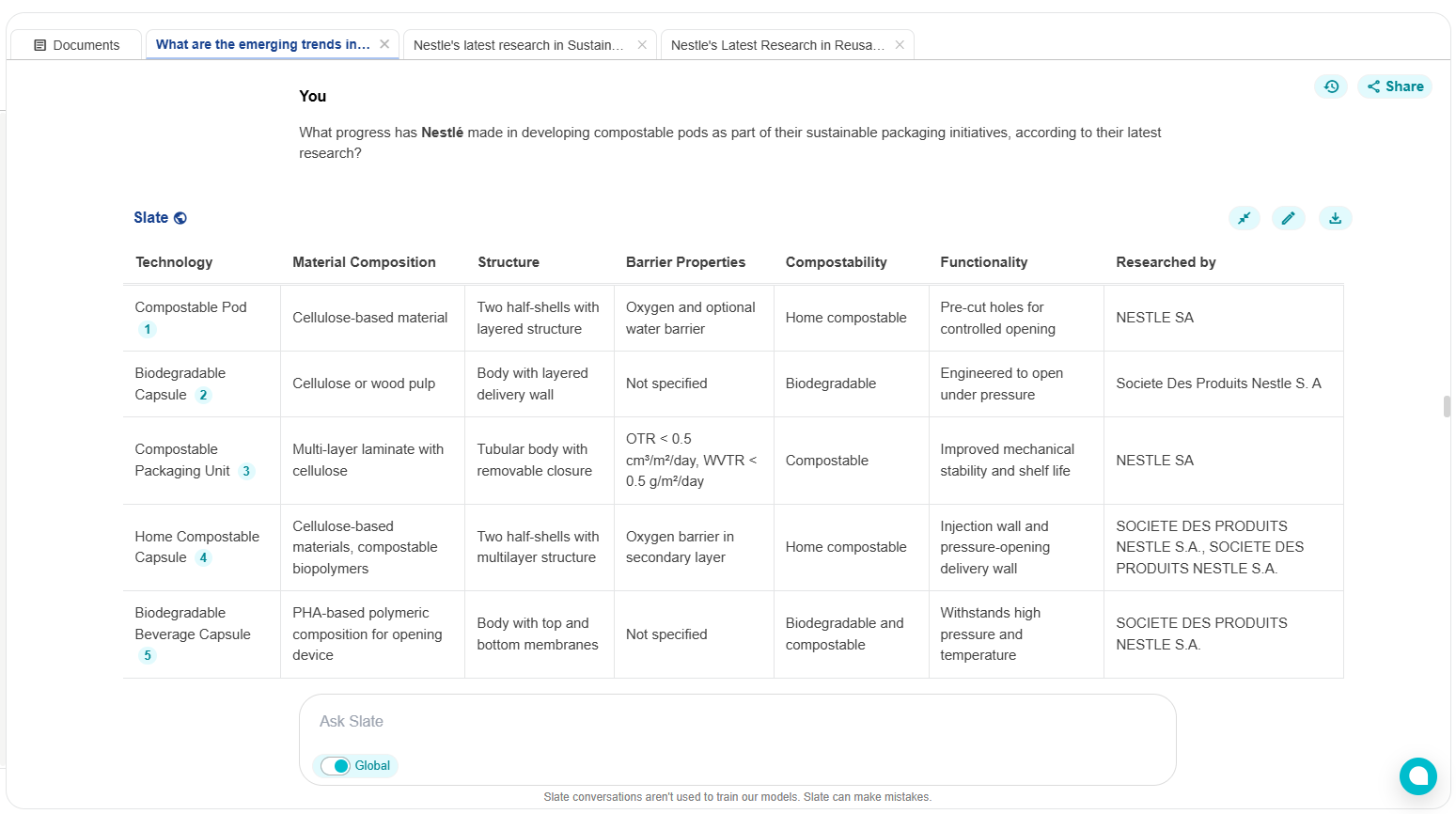

Using Slate (external innovation discovery tool), we tracked 5 patent filings from Nestlé between 2021–2024 related to compostable pod development. These patents revealed consistent improvements in barrier performance (up to 20%), material substitution, and brew-pressure optimization, highlighting the company’s focused push towards functional, sustainable packaging.

Such insights empower R&D and packaging innovation teams to identify whitespace opportunities, connect the dots, not just within one company’s ecosystem, but across the competitive landscape.

Let’s explore the key themes and features identified from the research:

1. Compostable Material Composition

Biodegradable Cellulose-Based Materials

At the core of Nestlé’s compostable pod innovation is cellulose-based materials. Cellulose is primarily derived from wood pulp or plant fibers, an inherently biodegradable material central to the company’s sustainable packaging strategy. Including molded pulp and paper as primary materials makes the pods home-compostable, meaning consumers can dispose of them in their home compost bins without contributing to landfill waste. This compostable structure significantly reduces the environmental burden compared to conventional plastic pods.

Use of Compostable Polymers

Nestlé has incorporated Polylactic acid (PLA) and Polybutylene succinate (PBS) into their design to enhance the durability and functionality of the pods. These compostable polymers reinforce the pod’s structural integrity, ensuring it can withstand the pressures of beverage extraction while maintaining the desired functionality. Additionally, these materials help enhance the pod’s barrier properties, ensuring the beverage remains fresh until consumption without compromising the environmental footprint.

By using biodegradable cellulose and compostable polymers, Nestlé addresses key consumer concerns around waste and sustainability, marking a significant move toward creating an environmentally responsible product line.

2. Innovative Pod Design

Layered Structure for Enhanced Functionality

One of the standout features of Nestlé’s compostable pods is the innovative, multi-layered design. The pods consist of a combination of layers that balance sustainability with functionality:

- Primary Paper-Based Layer: The outermost layer is made from paper, ensuring it is biodegradable and safe for home composting.

- Secondary Oxygen Barrier Layer: This layer ensures the beverage remains fresh by preventing exposure to oxygen and moisture.

- Tertiary Filter Layer: The inner filter layer ensures the beverage is brewed to the desired quality without compromising flavor or texture.

This multi-layered design is specifically engineered to maintain the quality and freshness of the beverage while ensuring that the packaging remains eco-friendly and fully compostable.

Pre-Cut Holes for Pressure Release

Another distinctive feature is the pre-cut holes or scratches integrated into the primary layer of the pods. These strategically placed openings enable the pod to open efficiently under pressure during brewing, allowing smooth and quick beverage extraction. The thoughtful design minimizes any risk of pressure buildup inside the pod, ensuring optimal functionality without sacrificing the pod’s integrity or compostability.

3. Enhanced Barrier Properties

Oxygen and Moisture Barriers

Ensuring that the beverage inside the pod maintains its quality is critical to consumer satisfaction. Nestlé’s compostable pods feature an advanced oxygen and moisture barrier in the secondary layer of the design. By incorporating materials like PLA and Calcium Carbonate (CaCO3), Nestlé can protect the beverage from external elements that could degrade flavor or freshness. This barrier system is crucial for meeting functional and environmental standards, allowing for the same high-quality beverage experience that consumers expect.

Advanced Sealing Techniques

Sealing a pod is equally essential for preserving freshness and ensuring no leakage issues during brewing. Nestlé has introduced an annular flange in the pod’s design, a feature that employs varying porosity to improve the pod’s seal. This innovation enhances pod usability and ensures eco-friendly sealing without the need for traditional plastic sealing methods.

These advanced sealing techniques improve the pod’s functional performance and reduce its reliance on non-compostable materials, further supporting the company’s sustainability goals.

4. Home Compostability and Environmental Impact

Meeting Compostability Standards

Nestlé’s compostable pods are engineered to meet rigorous compostability standards, such as the EN 13432 standard in Europe, which governs the requirements for biodegradable and compostable packaging. This certification ensures that the pods will break down effectively in a home composting environment, addressing the significant issue of single-use plastic waste. This aligns with Nestlé’s goal to transition toward more sustainable packaging solutions, directly responding to global environmental challenges.

By ensuring their pods meet stringent compostability standards, Nestlé is positioning itself as a leader in promoting circular economy principles, which focus on reducing waste and fostering material recovery. This focus on home compostability caters to environmentally-conscious consumers and makes it easier for them to adopt eco-friendly behaviors without compromising convenience.

Track Nestlé’s Next Breakthrough in Sustainable Packaging

Nestlé’s advancements in compostable packaging offer a clear competitive advantage in a rapidly evolving market. Brands that lag in embracing these innovations may face pressure from consumers and regulators, who increasingly prioritize sustainability.

Nestlé’s successful implementation of compostable pods underscores the importance of staying ahead of trends in packaging sustainability. To maintain competitiveness and remain aligned with future regulations, companies should closely monitor Nestlé’s ongoing efforts and explore similar sustainable innovations within their packaging strategies.

With Slate – an external innovation discovery platform

- Access consolidate Nestlé’s latest packaging R&D and innovations from diverse sources (patents, research reports, and scientific literature) into one actionable view

- Explore new packaging solutions with detailed performance and environmental impact data

- Monitor competitors’ latest material innovations, packaging strategies, and technology trends to inform your R&D roadmap

- Get data-backed answers to your packaging innovation questions via Slate’s AI research assistant