The global multilayer flexible packaging market was valued at approximately USD 168.92 billion in 2024 and is projected to reach around USD 283.55 billion by 2034, growing at a CAGR of 5.32% from 2025 to 2034. This surge underscores a fundamental industry tension, as complex multi-material structures preserve freshness and shelf life but remain among the most difficult to recycle at scale.

At the same time, regulatory bodies and sustainability mandates are becoming increasingly stringent. The European Union’s Circular Economy Action Plan aims for a 55% recycling rate in the packaging sector by 2030, with a focus on enhancing recycling methods for multilayer packaging.

In response, leading FMCG companies are rethinking packaging from the ground up. Nestlé, in particular, has emerged as a proactive player. The company has invested £7 million in a recycling plant in Durham, UK, to transform hard-to-recycle flexible plastics into reusable pellets for new packaging materials.

Meanwhile, research into solvent-based recycling processes has shown promise, achieving recycling rates exceeding 99% for multilayer flexible packaging waste. This indicates that the technical feasibility of circular packaging is no longer in doubt. The question now is who will commercialize it first, and at scale.

Latest Research and Innovation in Recyclable Multi-layer Laminates by Nestlé

Nestlé’s approach to sustainable packaging is grounded in rigorous material science, lifecycle thinking, and compliance with emerging global regulations. As part of its long-term vision, the company has focused on improving the recyclability of multi-layer laminates without compromising barrier performance or mechanical integrity.

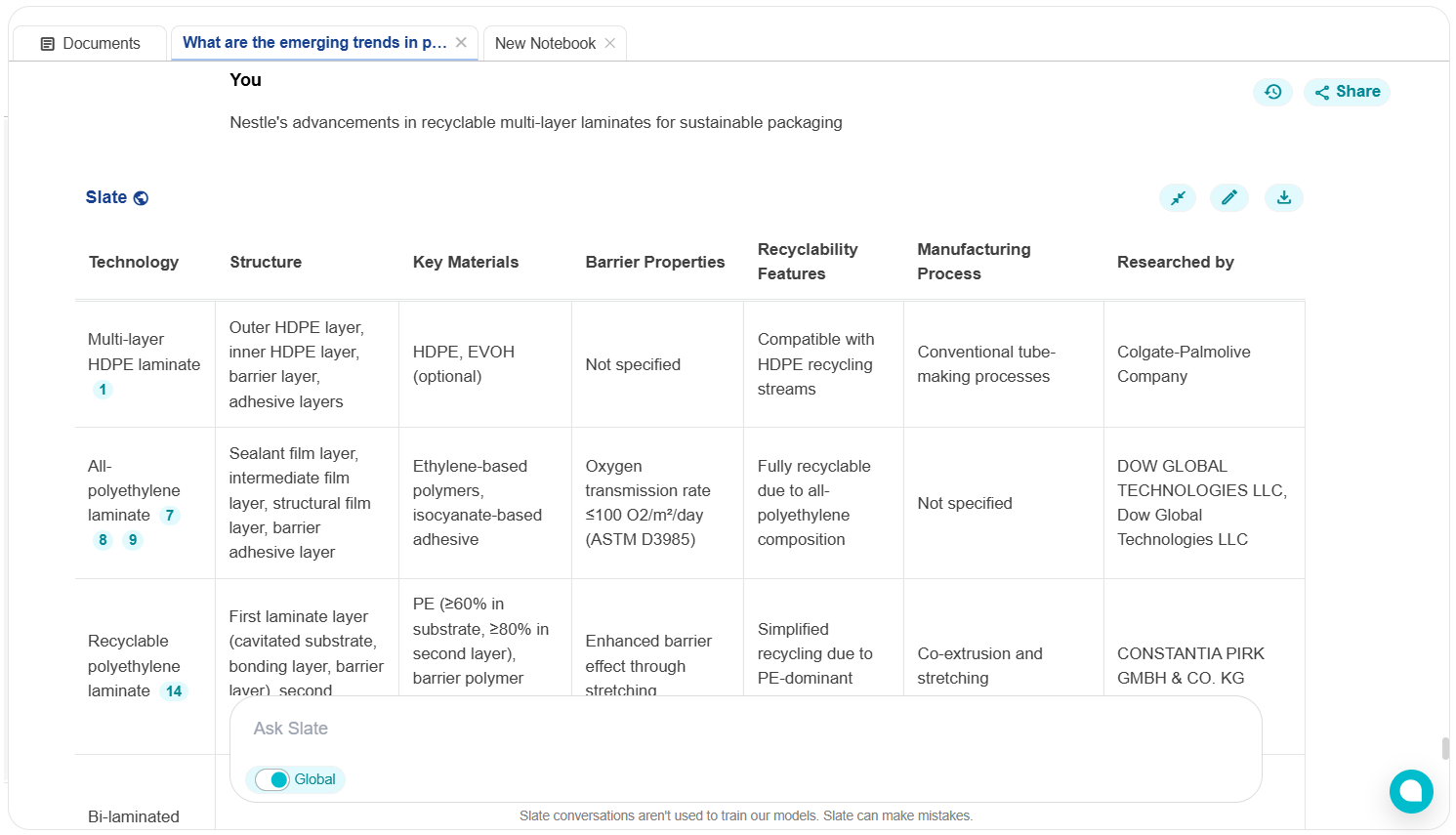

The image below highlights Nestlé’s latest advancements in recyclable multi-layer laminates for sustainable packaging.

To deepen visibility into the advancements, researchers are turning to tools like Slate to gain deeper insights into advancements by synthesizing fragmented data from patents, academic research, and pilot studies. It helps identify competitor innovations, allowing users to compare and analyze technologies based on parameters like material composition, barrier properties, recyclability, and manufacturing processes.

Nestlé is conducting research in different types of laminates including multi-layer HDPE laminate, all-polyethylene laminate, and recyclable polyethylene laminate. This research underscores Nestlé’s commitment to sustainable packaging solutions and provides valuable insights into emerging trends in the packaging industry.

Let’s explore the key themes and features identified from the research:

1. High-Density Polyethylene (HDPE) Structures

Nestlé is replacing traditional multilayer combinations with high-density polyethylene (HDPE)- based laminates. These laminates ensure shelf stability, seal integrity, and product protection, particularly for semi-moist or oxygen-sensitive goods.

HDPE Layers for Recyclability: Nestle’s packaging solutions often use HDPE for both outer and inner layers, with a barrier layer in between. This design ensures compatibility with existing HDPE recycling streams, avoiding non-recyclable materials like low-density polyethylene (LDPE) and polypropylene (PP).

Mechanical and Thermal Properties: The use of HDPE maintains the necessary mechanical and thermal properties, making the packaging suitable for various consumer products while enhancing recyclability.

This development aligns Nestlé’s packaging portfolio with design-for-recycling principles and regulatory frameworks like the EU Packaging and Packaging Waste Regulation (PPWR).

2. Barrier Layer Innovations

Nestlé’s engineers have tackled the barrier challenge using ethylene-vinyl alcohol (EVOH) and vacuum-deposited metal oxide layers, such as aluminum oxide (AlOx).

EVOH and Metallization: Ethylene-vinyl alcohol (EVOH) and metallized layers (e.g., aluminum oxide) provide necessary barrier properties without compromising recyclability. These materials help maintain low oxygen and water vapor transmission rates.

Selective Barrier Materials: The use of specific barrier materials like polyamide or ethylene-vinyl alcohol copolymer in minimal thickness enhances barrier performance while facilitating recycling.

Moreover, Nestlé is experimenting with selective barrier positioning and thickness optimization, reducing material use while maintaining barrier efficacy. These findings support circularity without compromising product preservation.

3. Reduction in Material Complexity

Nestlé’s research includes a move from traditional tri-laminated to bi-laminated and all-polyethylene (PE) laminate structures.

Bi-laminated Structures: Transitioning from tri-laminated to bi-laminated structures reduces material usage and enhances recyclability. This approach aligns with sustainable development goals by minimizing environmental impact.

All-Polyethylene Laminates: The development of all-polyethylene laminate structures ensures the entire packaging is recyclable, addressing challenges associated with traditional multi-material laminates.

This innovation streamlines recyclability and supports Nestlé’s Life Cycle Assessment (LCA)- driven material selection process, ensuring every design change has a net-positive environmental impact.

4. Innovative Recycling Techniques

Nestlé is investing in novel delamination and compatibilization techniques to further enhance the recyclability of multi-layer laminates.

Delamination and Compatibilization: Techniques such as delamination and selective dissolution-reprecipitation are explored to separate components and enhance recyclability. These methods aim to improve the recycling of multi-layer packaging.

Localized Adhesion and Water-Soluble Layers: Innovative designs that facilitate the separation of layers, such as localized adhesion patterning and water-soluble layers, are being tested to improve recyclability.

Track Nestlé’s Next Move in Sustainable Packaging

Nestlé’s packaging strategy reflects its deep scientific investments into scalable, recyclable, and performance-compliant laminate structures. By re-engineering packaging at the molecular and structural level, Nestlé anticipates future regulations and actively shapes the infrastructure and standards that will define the next generation of flexible packaging.

Companies that fail to evolve beyond traditional multi-material composites risk losing market share to more agile, innovation-led rivals. Nestlé’s alignment with recyclability protocols and functional parity in performance gives it a first-mover advantage in sustainable packaging ecosystems.

Use Slate — a competitive R&D intelligence platform to continuously monitor how Nestlé and other global leaders are advancing in packaging R&D.