Packaging accounts for over one-third of global municipal solid waste, and plastic packaging alone constitutes approximately 36% of all plastics produced, with a mere 9% being recycled globally. As governments tighten regulations and consumers demand transparency, packaging becomes a boardroom priority.

For Nestlé, one of the world’s largest food and beverage companies with a packaging footprint of over 4.5 million metric tons annually, the pressure is especially high. Beyond reputational risk, the company faces mounting regulatory expectations, including the EU’s target to make all plastic packaging reusable or recyclable by 2030.

This environment has triggered a critical shift in Nestlé’s strategy and rather than viewing sustainability as a compliance task, they’re embedding circularity at the core of its packaging R&D.

This article explores Nestlé’s approach to building scalable, reuse-friendly packaging systems, their underlying material science, and the structural innovations driving this pivot.

Nestlé’s Recent Research in Reusable Packaging Systems

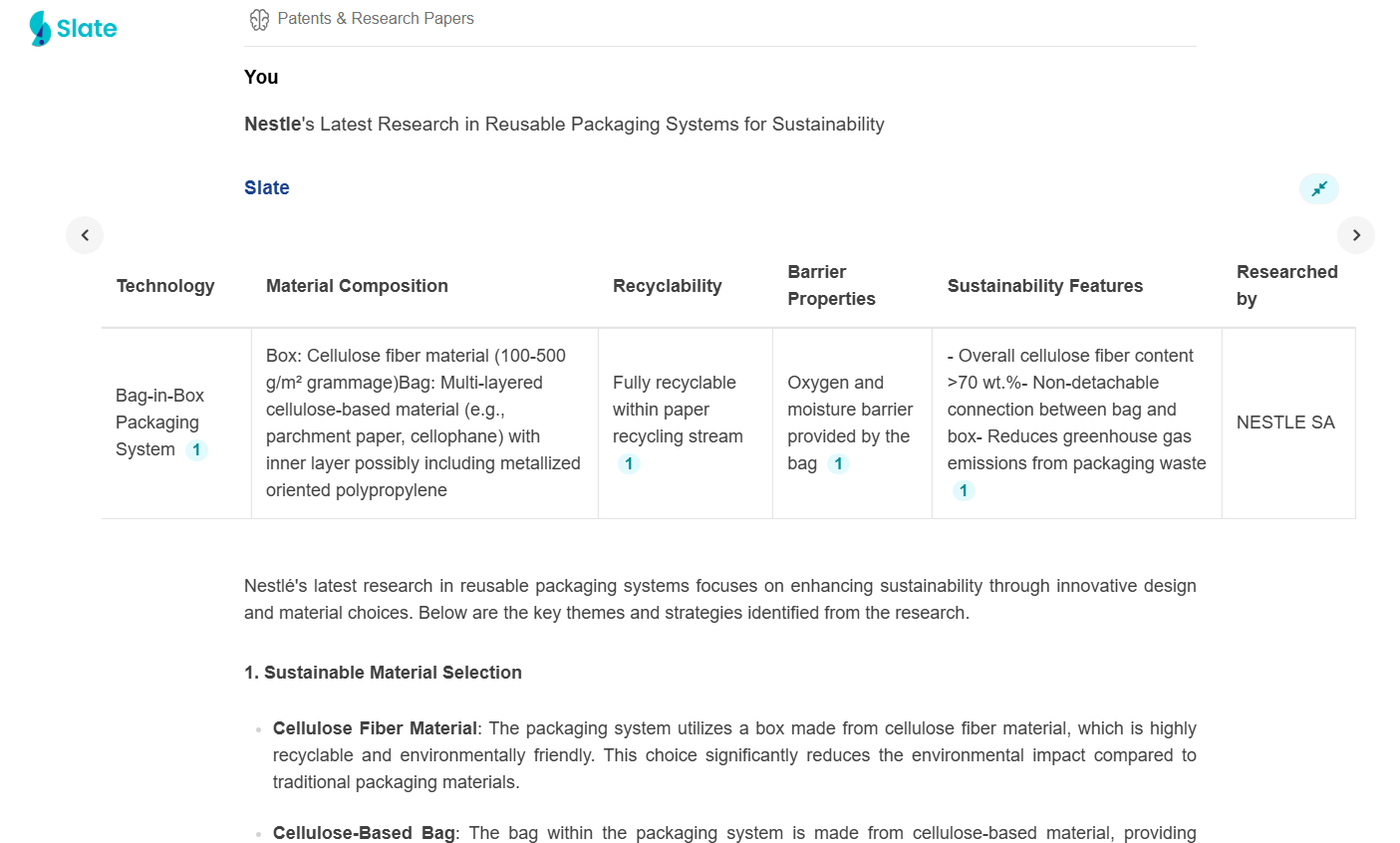

Nestlé’s latest research in reusable packaging systems focuses on enhancing sustainability through innovative design and material choices. They are shifting from incremental improvements to system-level packaging redesigns that align with circular economy principles.

For R&D leaders, tracking such shifts across industry players isn’t always straightforward. Research tends to be scattered across patent, research papers and technical reports, making it difficult to understand what a company is doing and where it’s heading.

That’s where tools like Slate come in. Slate is an AI-powered research tool that consolidates this fragmented landscape, offering a comparative lens into packaging R&D across industry players.

Let’s explore the key themes and features identified from the research:

1. Sustainable Material Selection

Nestlé’s latest packaging solution is anchored in cellulose fiber-based materials, offering a notable departure from conventional petroleum-derived plastics. This choice is strategic:

Cellulose Fiber Material: The packaging system utilizes a box made from cellulose fiber material, which is highly recyclable and environmentally friendly. This choice significantly reduces the environmental impact compared to traditional packaging materials.

Cellulose-Based Bag: The bag within the packaging system is made from cellulose-based material, providing essential oxygen and moisture barrier functions. This ensures product integrity while maintaining sustainability.

By selecting a material with naturally low environmental impact and high recyclability, Nestlé addresses ecological and functional requirements while maintaining a balance that is often challenging to achieve in food-grade packaging.

2. Recyclability and Environmental Impact

The packaging system has been meticulously engineered for seamless integration into the paper recycling stream. Key design elements that enable this include:

Recyclable Design: The entire packaging system is designed to be recyclable within the paper recycling stream. This feature enhances its environmental sustainability by facilitating easier recycling processes.

High Cellulose Fiber Content: With a cellulose fiber content exceeding 70 wt.%, the packaging system ensures high recyclability, aligning with sustainability goals and reducing greenhouse gas emissions associated with packaging waste.

3. Structural Innovations

Nestlé’s design philosophy reflects a clear trend toward modular reuse. Several innovations stand out:

Multi-Layered Structure: The bag features a multi-layered structure with an outer layer of cellulose-based material and an inner layer that includes materials like metallized oriented polypropylene (OPP). This design provides necessary barrier properties while supporting recyclability.

Non-Detachable Bag-Box Integration: Prevents component separation during disposal, ensuring the entire package can be processed as a single recyclable unit. This minimizes contamination in recycling streams, increasing the effective recycling rate.

These design choices offer potential for reuse-oriented delivery models (e.g., refill stations, returnable containers) and for reducing consumer friction, a critical factor in adoption rates for sustainable packaging.

Explore Nestlé’s Next Innovation in Sustainable Packaging

Nestlé’s efforts are far from superficial. They intend to lead packaging innovation by addressing systemic constraints (like recycling infrastructure) and product-level requirements (like barrier performance).

Nestlé’s deep integration of material science and systems thinking provides a roadmap for competitors and also a wake-up call. As sustainability metrics become embedded in procurement, investment decisions, and consumer choice, companies unable to pivot at the pace of leaders like Nestlé risk more than just brand damage.

Want to stay ahead of Nestlé’s next breakthrough in packaging R&D? Use Slate to monitor real-time research movements, patent filings, and material partnerships.