With packaging waste under global scrutiny and regulations like the EU’s PPWR aiming for full recyclability by 2030, Nestlé is making plant-based barrier coatings a core R&D priority. The company also has a clear roadmap to make 100% of its packaging recyclable or reusable by 2025.

Nestlé’s Quality Street confectionery range is a standout case in point. The company replaced dual foil and cellulose wrappers with FSC-certified paper coated in a vegetable-based barrier. This shift maintains product integrity by preventing oil and fat migration while making the packaging recyclable through standard curbside paper streams. This single move alone will eliminate 2.5 billion pieces of non-recyclable packaging from its global supply chain.

Behind this shift lies significant R&D effort in balancing recyclability with barrier performance, addressing challenges like oil migration, tear strength, and machinability. By cutting its plastic packaging weight by 35% and aiming for 95% recyclability by 2025, Nestlé is showing the industry that sustainable packaging is a core strategy for staying ahead.

For R&D leaders in the CPG, food, and materials sectors, Nestlé’s work offers a practical blueprint for scaling sustainable innovation and building packaging systems that are future-ready, compliant, and effective.

Nestlé’s Strategy on Plant-Based Barrier Coatings

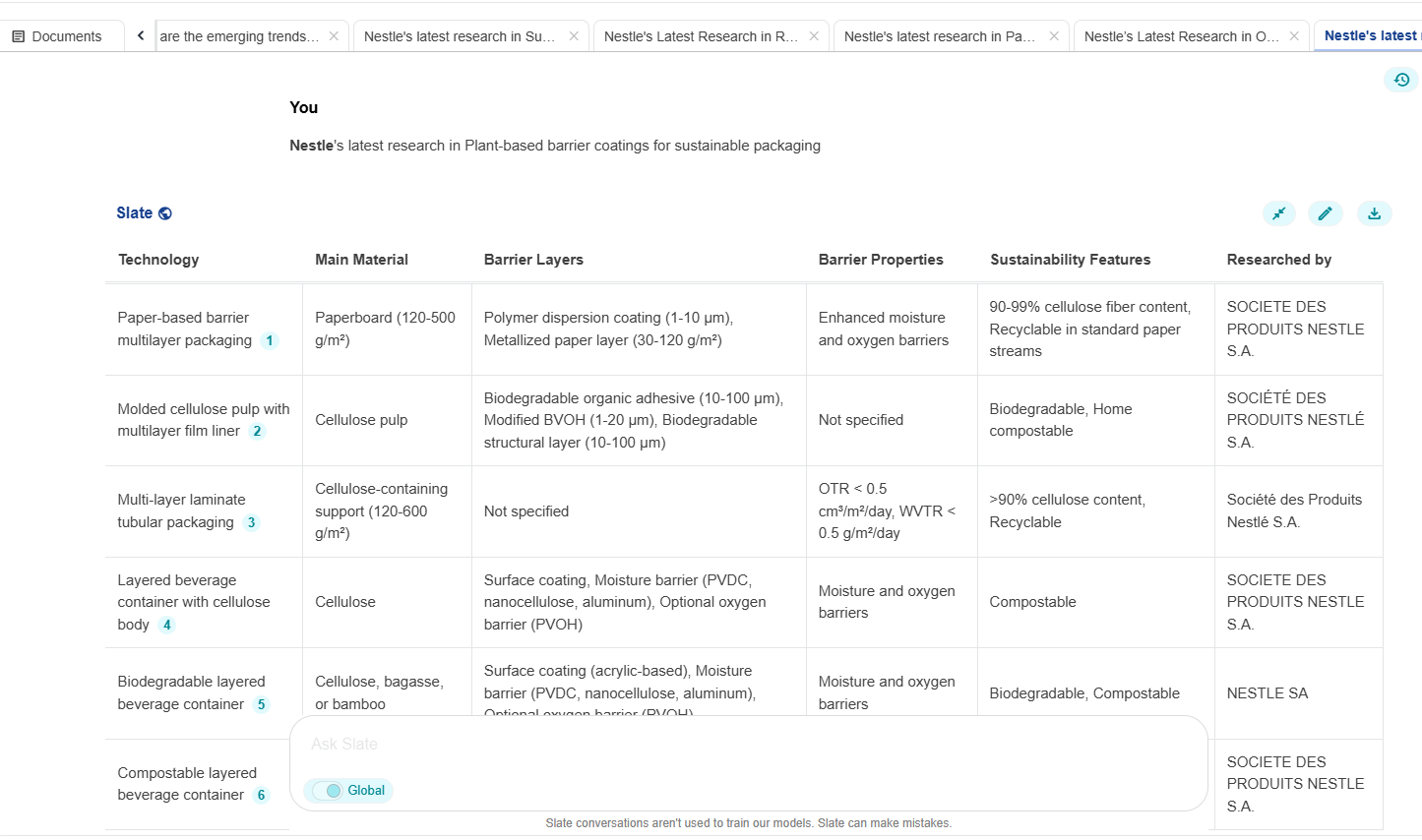

Nestlé’s latest research in plant-based barrier coatings for sustainable packaging focuses on developing innovative materials and structures that enhance recyclability, biodegradability, and barrier properties.

For R&D leaders aiming to track such advancements and stay competitive, simply reading market reports or scattered publications isn’t enough. What’s needed is a structured view of where companies like Nestlé are investing, what materials they’re prioritizing, and how those choices affect recyclability, compostability, and regulatory alignment.

That’s where a research intelligence platform can help. Slate, our AI-powered innovation discovery platform, aggregates insights from patents, scientific publications, and technical documentation. It helps R&D and innovation teams conduct a literature review and go beyond surface-level findings by enabling custom parameter filtering, benchmarking, and multi-attribute comparison.

Whether you’re exploring the feasibility of a new fiber-based packaging material or assessing competitor readiness, Slate transforms scattered data points into a strategic decision-making advantage.

Let’s explore the key themes and features identified from the research:

1. High Cellulose Content for Recyclability

Nestlé’s pivot toward paper-based multilayer packaging marks a sophisticated response to the recyclability challenge. The company is developing multilayer packaging material with a high cellulose fiber content (90-99% by weight), which facilitates recycling in standard paper streams.

Paper-Based Barrier Multilayer Packaging: The structure includes a polymer dispersion coating, a paperboard layer, a water-based adhesive layer, and a barrier metallized paper layer. This design improves moisture and oxygen barrier properties while ensuring recyclability.

Cellulose-Containing Support Layer: A multi-layer laminate structure with a cellulose content exceeding 90% is used to create a packaging unit with effective oxygen and moisture barriers. This design ensures recyclability and maintains superior barrier performance, enhancing packaged food products’ shelf life and safety.

This innovation presents a scalable alternative to polymer-heavy multilayers. Competitors relying on mixed-material packaging may face obsolescence under stricter Extended Producer Responsibility (EPR) regimes unless similar high-cellulose formats are adopted.

2. Biodegradable and Compostable Solutions

Nestlé is concurrently innovating in the domain of home-compostable, molded pulp-based packaging.

Molded Cellulose Pulp Body with Multilayer Film Liner: This packaging solution features a rigid or semi-rigid molded cellulose pulp body with a multilayer film liner made from biodegradable polymers. The design eliminates the need for tie layers, enhancing biodegradability and simplifying manufacturing, making it suitable for home compostable packaging.

Compostable Beverage Containers: These containers are designed with a cellulose body and multiple coating layers to provide moisture and oxygen barrier functions. The use of biodegradable pulp materials like cellulose, bagasse, or bamboo ensures rigidity, while the coatings enhance barrier properties. This format addresses the market gap where rigid barrier performance is needed but traditional PET/HDPE containers fall short on sustainability.

Nestlé’s work here is particularly relevant for brands in beverages, dairy, and ready-to-drink segments. Companies relying on industrially compostable plastics like PLA may find themselves at a cost and regulatory disadvantage.

3. Advanced Barrier Coatings

Barrier functionality has historically conflicted with recyclability and compostability. Nestlé’s exploration of advanced materials and deposition methods attempts to overcome this.

Moisture and Oxygen Barrier Coatings: The research explores the use of materials such as Polyvinylidene dichloride (PVDC), nanocellulose, microcellulose, silicon nitride, or aluminum for moisture barriers, and compostable plastic films like Polyvinyl Alcohol (PVOH) for oxygen barriers.

These coatings are applied through techniques like spraying, lacquering, or plasma coating, providing effective protection while maintaining compostability.

Decode Nestlé’s Next Move in Eco-Friendly Packaging

Nestlé’s multi-pronged research into plant-based barrier coatings is reshaping what sustainability means in packaging. By fusing biobased innovation with manufacturing scalability, Nestlé is future-proofing its global packaging formats, preemptively aligning with evolving regulatory frameworks, and embedding sustainability at the material level.

These innovations are raising the baseline for Nestle’s competitors. For them, failing to engage at the material science level may soon translate to a real market disadvantage, especially in jurisdictions that are pushing for Design for Environment (DfE) and circular economy mandates.

Want to stay ahead of Nestlé’s next moves in sustainable materials, food science, or packaging tech? Use Slate to monitor patents, scientific publications, and R&D activity in real-time. Get insights before they go mainstream.